Consistent sustainability in the textile industry can only be achieved through the digitization of every step in the manufacturing process. Brands and retailers are already making major contributions to this transition. Now, further steps in the value chain must follow with the help of key digital technologies, despite facing certain hurdles.

Consumers are increasingly demanding that their clothing be manufactured sustainably; they want to know that their garments were produced under ecologically and socially acceptable conditions. This requires transparency and traceability throughout the entire textile supply chain. Brands and retailers already recognize this need, and they are now in the process of opening their supply chains via blockchain technology. Every brand with at least a minimum sense of responsibility is striving to inform customers about their sustainability initiatives as comprehensively as possible by providing ample information about how their products are manufactured. Despite this significant progress, however, there are still hurdles that the industry must overcome.

Hurdles in the Realization

One challenge to the sustainability initiative is that the textile supply chain is one of the most segmented industries in the world. According to McKinsey’s 2017 State of Fashion study, the apparel industry is worth $2.4 billion. For comparison, the market valuation of the automotive industry is $2.2 billion, according to the International Organization of Motor Vehicle Manufacturers (OICA). The difference, however, is that the top 10 brands in the automotive industry control 80% of the market, whereas the top 10 brands in the fashion and apparel industry account for only 10% of the market. This high level of segmentation is partially responsible for the difficulties in realizing the transparency consumers expect. For example, according to the Fashion Revolution organization, while 40% of brands knew their tier 1 suppliers in 2020, only 7% knew their raw material suppliers. What could explain this gap?

Traditional Corporate Mentality Meets Digitalization

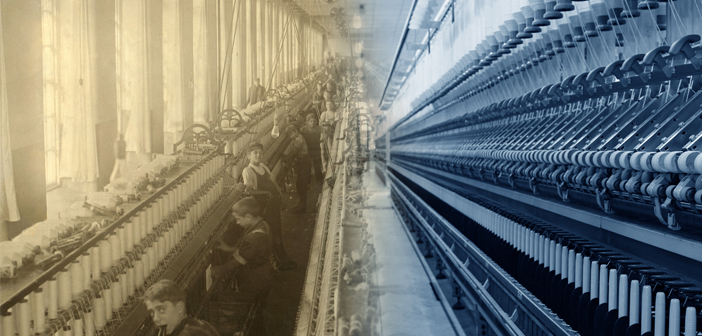

The companies between tier 1 and raw material suppliers are mainly spinning mills, knitting mills and weaving mills. Among them, a traditional corporate mentality tends to prevail. For example, the way that machines work in a spinning mill today is basically the same as it was 200 years ago, albeit much faster and more automated. Textile machinery manufacturing itself also has a long tradition; many of the major manufacturers have been active in the industry for over 100 years.

Despite the prevalent traditions at these mills, however, the spinning machine manufacturers have spent the last few years working to connect the production steps with each other through machine-to-machine networks and to collect further data on the production process via IoT. With the help of artificial intelligence, errors or faulty patterns are automatically detected and eliminated from this data at an early stage without human intervention. Experts predict that the overall efficiency of the processes and the quality of the end product can be increased by such interaction between these technologies. The prerequisite, of course, is an open system, which enables pattern recognition through a large amount of data.

The progress of these textile mills makes it clear that true sustainability can only be achieved through the consistent application of digital technologies at all levels. Digitalization is thus becoming the driver of sustainability in the textile industry.

Recommended further reading: AI The Future Of Textile Industry-Maj Gen OP Gulia – BW Businessworld