Landfills are one of the largest emitters of methane into the atmosphere, yet one of the least invested in abatement. The golden years of the Kyoto Protocol and the Clean Development Mechanism, when credits were easily allocated between countries, are over, and new investors are reluctant because of a lack of clarity about the return on investment. Well-publicised cases of green-washing and fraud in the issuance of carbon credits have made matters worse. To mention some public cases of know fraud in issuence of carbon credits there is the case of C-Quest Capital in USA, the fraud in Bulgary on EU’s Emissions Trading System (ETS) and the falsification of data in China. See reference links.

Today, the sector can only rely on national programmes or the sale of carbon credits on the voluntary market. The generation and certification of these credits is currently carried out by third party certification bodies and auditors in a manual way, with data being collected every six months, analysed and validated by an inspector before being certified. The whole process is bureaucratic, slow and inefficient. Typically, under the current system, an investor could wait up to five years to receive the first payment. A reliable, transparent, automated and scalable data collection and processing system could turn the tide and unlock much-needed investment in the sector.

This blog affords this topic.

Blog

Methane (CH₄) is a greenhouse gas (GHG) that, by mass, has approximately 25 times the global warming effect of carbon dioxide (CO₂) over a 100-year time horizon. This factor is known as the Global Warming Potential (GWP) of a gas. To account for different GHGs, emissions are commonly expressed in carbon dioxide equivalent (CO₂eq), calculated by multiplying the mass of the gas emitted (in tonnes) by its GWP.

Currently, landfills worldwide contribute about 11% of anthropogenic methane emissions.

In developed countries, the average municipal solid waste (MSW) generation is approximately 1 kg per person per day. This means a city with 1 million inhabitants produces about 365,000 tonnes of MSW annually, which must be landfilled in the absence of incineration facilities.

Since 40–60% of MSW is biodegradable, it typically decomposes anaerobically, producing methane. Peak methane production usually occurs 2 to 3 years after waste deposition, resulting in approximately 5 million cubic meters (m³) of landfill gas per year.

To put this in perspective, the methane emissions (in CO₂eq) from such a landfill are comparable to the annual emissions of around 38,000 diesel cars in Europe, each driving an average of 10,000 kilometers per year.

A country like South Africa for example have more than 1000 oficial landfills registered and less than 20 have proper degassing systems installed, and only few of them registered under a system of certified emissions reduction where in the best case the data is transmitted openly to an on-premises services.

Currently there are only few companies providing Measurement, Reporting and Verification (MRV) of emission reductions as a service in an automated and certified manner (TrustVal as example).

In this scenario the importance of an automated and reliable system to account for emission reductions is double. On one side it could atract investments to a usually neglected sector, on the other hand it can produce a significant impact in the much needed effort of reducing the global warming.

The challenge

The implementation of such idea in an environment so far away from the technlogical sector poses several challenges. In this blog we explore some of the most common problems and listed some ideas to overcome the challenge.

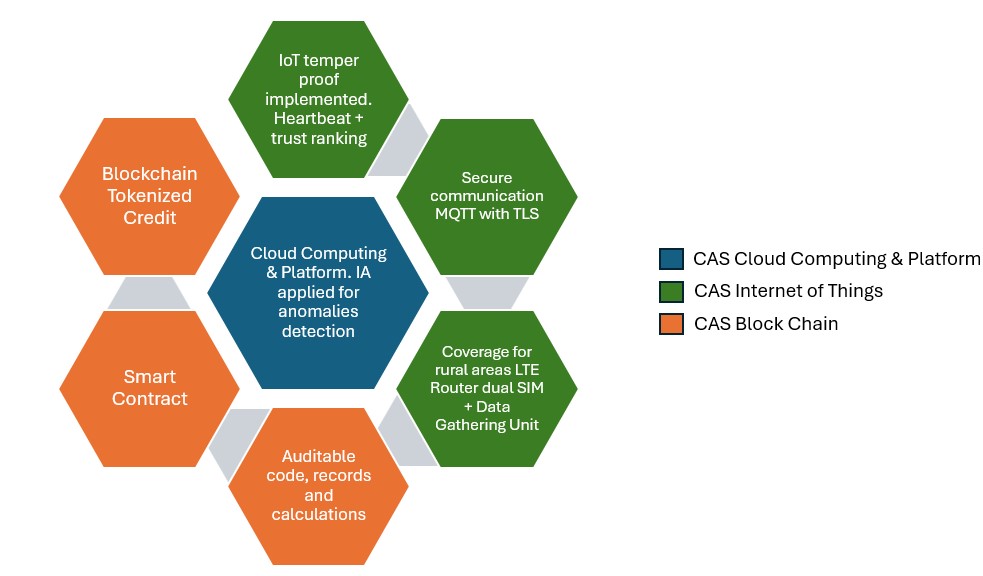

Potential tempering

One way to reduce the likelihood of tampering with, manipulating or replacing calibrated critical devices used for calculations or carbon credits would be to ensure that the collected data includes metadata about the instrument, such as the serial number or MAC address. These values should be defined in the project protocol, and a validation function should check them to authorise their use, only data coming from previously approved and calibrated devices can be considered for further process.

A system of Heartbeat or signal ping can be installed to confirm that the instruments has not been disconnected, even when the system is not runnig, and a degree of confidence can be assigned to the data coming from long time connected instruments as a trust ranking of information.

In a second step to improve this aspect artificial inteligence tools (AI) can be incorporated in the process to detect anormalities and paterns in the data (outbounder values detection).

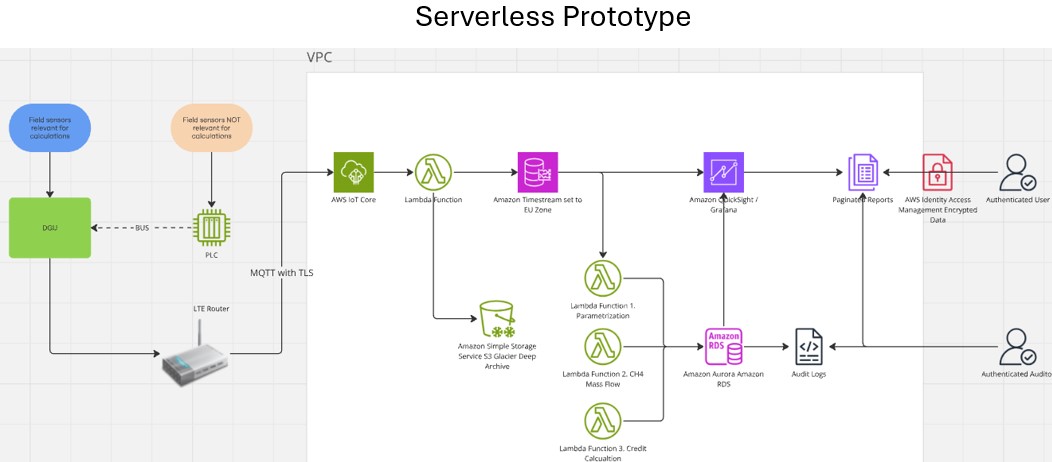

Another measure against tampering could be to physically separate the entry point for critical instruments from that for purely informative instruments. Instruments connected to the Programmable Logic Controller (PLC) pose a risk that by modifying the source code of the controller the amount reported is artificially increased, or local access to the PLC could allow unauthorised manipulation of the data before it is transmitted to the cloud solution. A potential solution to minimise this risk would be to connect all instruments considered critical for calculating credits to a validated Data Gathering Unit (DGU) that purely transmitts the data to the router. The exchange of information between the PLC and the DGU can happens via BUS.

Availability in remote places

Landfills are usually located in remote areas, sometimes in deep valleys, where a reliable internet connection cannot be guaranteed. One potential solution is to use Long Term Evolution (LTE) routers with dual SIM cards and storage capacity. This means that transmission does not depend on a LAN connection, but rather on 4G. Using two different providers also provides redundancy in case of an interruption. Finally, a router with built-in memory can ensure that data is transmitted without loss as soon as the connection is re-established. The data collected is time stamped and gaps or abnormal time intervals between the stamps should trigger alerts in the cloud system.

The system can be made more robust by adding a battery retrofitted with a photovoltaic cell to minimise unstable power networks and avoid the short disconnections and restarts of PLCs and data gathering units that occur when relying on backup power generators.

Auditable system

The issuance of emissions reduction credits is a process that requires third-party certification; therefore, any code used for automatic calculations must be clear, transparent, and auditable.

The firmware used in devices such as the router and DGU must be versioned and approved in the project protocol to ensure consistency and prevent unauthorised upgrades.

The application performing the credit calculation should be open-source, versioned, and able to generate audit logs. At any time, a certification party should be able to access these logs independently and verify each step of the calculation for each line of data. One credit corresponds to one tonne of CO₂eq, which is the result of the accumulation of instant calculated values. Therefore, for each tonne calculated, it should be possible to trace the source data used to calculate that specific credit.

Public Transparency

Adding a public static web page presenting the online process values of each registered project could help national or governmental authorities to better control the real working conditions of each site without needing to visit it.

Generating credits through a smart contract and publishing them on a public blockchain would make the whole system tamper-proof, auditable and transparent.

Security

Cyber attacks on the system could lead to fraud, so a robust security strategy is essential for the project.

Using a Virtual Private Cloud (VPC) to develop the cloud solution with zero trust policies, Identity and Access Management (IAM), and Multi-Factor Authentication (MFA) is mandatory.

Using the secure Message Queuing Telemetry Transport (MQTT) protocol with Transport Layer Security (TLS) should provide a secure communication channel between the broker and the cloud server.

Technical idea

A non-industrial first prototype can set a proof of concept with quick implementation, using the service packages provided by Amazon Web Services (AWS) in a serverless system. This would be a simplified version of the potential system and does not consider redundancies, high availability, high traffic volumes, applications, multiple instances, scalability, blockchains or big data analysis.

Links

EPA Overview of Greenhouse Gases

About Methane and landfill impact

Bulgaria Emissions Report fraud

Falsifyied Carbon Data in China

Hofstetter: Climate Impact Calculator

«About the Autor»

Guillermo is a mechanical engineer working in providing environmental solutions with focus in landfill’s impact mitigation. With 12 years of experience at Hofstetter Gastechnik AG which core business is the manufacturing of systems to treat the two main contaminant effluents from landfills, the gas and the leachate.

Guillermo Pomphile attends the CAS Cloud Computing & Platform at HSLU